Bulk Fertilizer Blending Plant

Mining, chemical industry, building materials, fertilizer plants, etc.

1-30 t/h

7.5-22 kw

3-10 mm

BB fertilizer, the full name is bulk blending fertilizer. Also, BB fertilizer is mainly consists of two or three nutrients of the nitrogen, phosphorus and potassium. Besides, BB compound fertilizer is made by mixing several granular single fertilizers or compound fertilizers in a certain proportion. Its main feature is that the ingredients and proportions can be flexibly adjusted according to different crops and soil conditions. In fact, BB fertilizer is very popular in agricultural production because it can precisely meet the specific nutrient needs of various crops.

How to configure a BB fertilizer granulation production line?

For the BB fertilizer granulation production line, the granulation process is an essential process. Different from the powder BB fertilizer production line, pelletization is to mix the BB fertilizer powder into pellets of uniform size and easy to apply. Granular BB fertilizer can not only improve the efficiency of fertilizer application, but also facilitate subsequent transportation and storage. Granulation is a very critical step, which directly affects the use effect and appearance quality of fertilizer. The following are 3 types of Shunxin BB fertilizer granulators

3 Types Shunxin BB Fertilizer Granulating Equipment For Sale

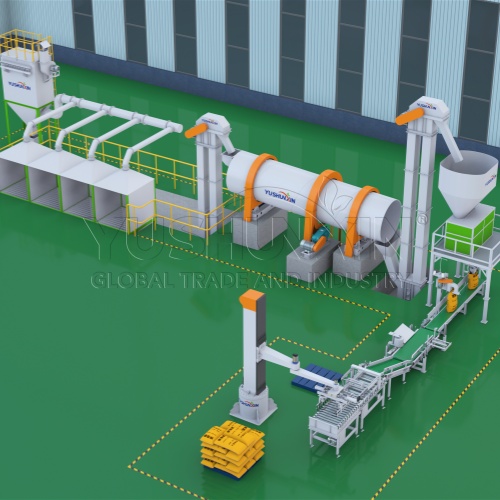

What Are The Essential equipment of BB fertilizer production line?

When setting up a BB fertilizer production line, there are several essential equipment to ensure effective and precise processing of fertilizers. The main processing equipment includes: automatic batching machine, BB fertilizer mixer, packaging machine, etc.

Batching system

The batching system is key to accurately weighing various fertilizer materials according to specific BB fertilizer recipes. It is consists of feeding system, weighing device, stock bin and conveyor belt.

If you want to save time and realize automated batching, then we have two Shunxin batching machines for you to choose from: dynamic automatic batching machine and static batching machine.

- Dynamic automatic batching system: Dynamic batching system is suitable for fertilizer production with continuous batching requirements. It can continuously deliver raw materials to the mixing system to achieve real-time dynamic batching. The process is fully automatic, allowing precise control of the raw material supply according to the formula. Dynamic batching system generally adopts electronic belt scales to strictly control the precise proportion of raw materials. This equipment is suitable for large scale and continuous BB fertilizer production. The automated system greatly improves production efficiency and reduces labor cost.

- Static batching machine: Static batching machine is of use in fertilizer production when raw materials need quantitative dosing. The static batching machine adds all the required raw materials into the batching container at one time according to the preset formula, and then mixes it once. This equipment is suitable for small scale BB fertilizer production and only requires manual feeding. It greatly saves time and production costs, and meets national measurement standards. It has the characteristics of simple design, low maintenance cost and easy operation.

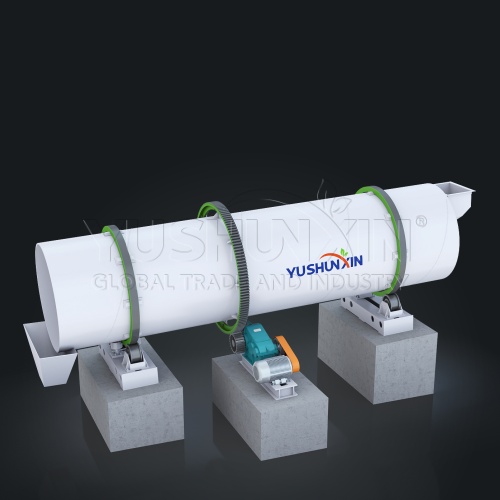

BB Fertilizer Mixer

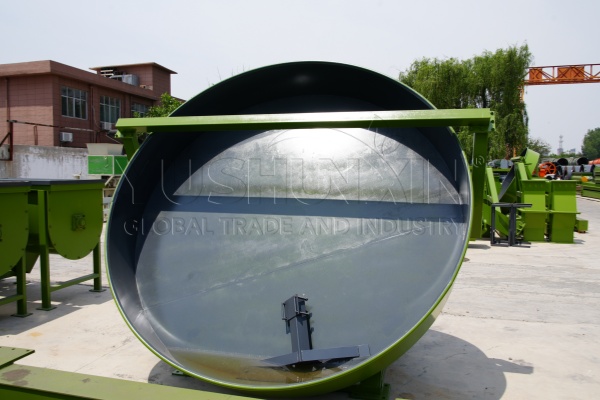

Shunxin BB fertilizer mixer is an indispensable equipment in the bulk blending fertilizer production line. It is mainly of use to evenly mix different types of raw materials (such as nitrogen, phosphorus, potassium fertilizers and trace elements, etc.) to ensure the nutritional balance of the final BB fertilizer product. We have 2 types of Shunxin BB fertilizer mixing machine, which is BB fertilizer mixer and drum type BB fertilizer mixer.

- BB fertilizer mixer can effectively and evenly mix different types of fertilizer raw materials. It is suitable for small-scale BB production plants with a production capacity of 1-5t/h. This type of mixer usually has the characteristics of high precision, fast speed and long service life, making it an ideal choice for BB fertilizer manufacturers.

- Drum type BB fertilizer mixer can achieve continuous high-efficiency production. Therefore, it is suitable for large scale BB fertilizer production. And the output can approximately reach 30-40 tons/hour. The mixer uses a rotating drum to effectively mix different types of fertilizer raw materials to achieve the desired uniformity. It has the characteristics of high efficiency and wear resistance, and we can customize the anti-corrosion lining according to customer requirements.

Automatic Packing Machine

Shunxin BB fertilizer automatic packing machine is an efficient packaging equipment that can complete the rapid packaging of BB fertilizers. This machine is widely of use in the production and packaging industries of various fertilizers. By using automatic packaging machines, fertilizer manufacturers can significantly improve packaging efficiency, reduce labor costs, and ensure consistent and accurate packaging quality.

3 characteristics of BB fertilizer

What should you take into consideration when setting up a BB fertilizer production line?

The BB fertilizer production line refers to a complete set of equipment and processes used to produce BB fertilizer. It is designed to mix several single fertilizers (such as nitrogen, phosphorus, potassium fertilizers and trace elements, etc.) or compound fertilizers in certain proportions to provide a variety of nutrients that plants need. The BB fertilizer production line is related to the quality and production efficiency of BB fertilizer. Obviously, it correlates to the effect of finished BB fertilizer. Moreover,the BB fertilizer production line has the characteristics of high-efficiency production, precise proportioning, and low cost. If you want to set up your own BB fertilizer production plant, then you are welcome to contact us for details about your specific needs.