Оn March 20th, 2024, we received an inquiry from Henry, a small mining entrepreneur in Golden, Colorado. Более того, he said they generate a significant amount of tailings—waste material from mining operations. Thus, they wanted a useful fertilizer production plan to transform 10,000 lbs of mine tailings into mineral fertilizer granules. Затем, our company quickly customized mineral fertilizer production proposal for Henry.

План грануляции удобрений на 5T/H American Mine Plant

<$60,000 Mine Fertilizer Machines

Based on Henry’s needs and raw materials, Юшунсин proposed a comprehensive mine fertilizer solution. And he said his company have the budget of 60,000 dollars to buy rock fertilizer equipment. Также, the process would begin with crushing, followed by grinding, грануляция, сушка, and packaging. Here’s a breakdown of the equipment proposed:

Mine Tailing Crushers

Jaw Crusher For Grinding Mine Tailing

Рэймонд Милл

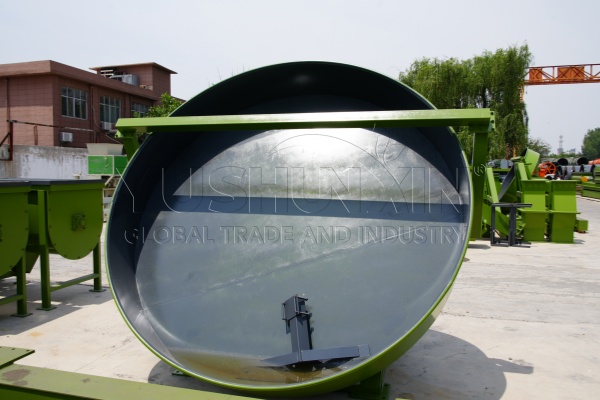

10,000 Lb/H Disc Granulator For Sale

Большой панельный панель для продажи

Другое вспомогательное оборудование

💲11,000 & 10,125

The Transportation Plan to USA

яn fact, we finished these mineral fertilize machines on May 18th, 2024. And we sent the trial running videos to Henry. Затем, he paid the balance on May 20th, 2024. Поэтому, our company arranged two 40GP containers for these equipment packaging to ship from Qingdao Port, Китай, to Denver, Colorado, with a total shipping period of 35 days. Кроме того, the total transportation cost is $8,090USD, including transit, customs clearance, and inland delivery. Окончательно, these machines was delivered to Henry’s factory in Golden, Colorado, on June 30th, 2024. Затем, we assigned technicians with on-site installation and training over three days, ensuring Henry’s team could operate the system smoothly.